The $50,000 Decision Tax: How Data Silos Are Starving Your Operations of Intelligence

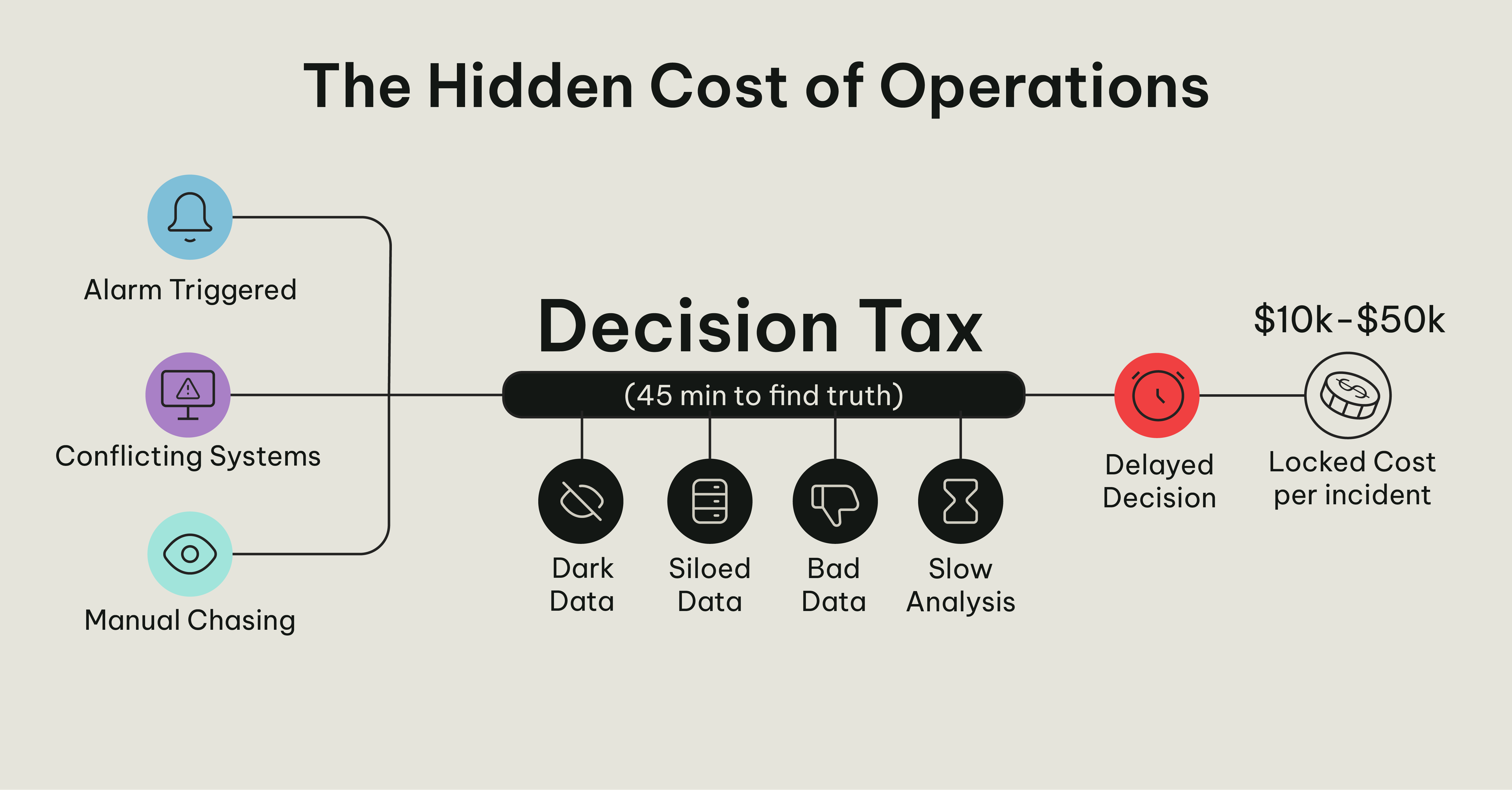

For the Operations Manager, the morning dashboard is a hall of mirrors. The MES shows a critical machine running, but the ERP shows its output missing from inventory. The project schedule in the Primavera file is green, but the superintendent’s WhatsApp messages from the site tell a story of delay. You have more data than ever, but the truth feels harder to grasp. That gnawing feeling? It’s not imposter syndrome. It’s the tangible cost of decision latency, and it’s bankrolled by a fundamental architectural failure in how your company manages intelligence.

The old lie was that more data equals better decisions. The new, painful truth is that data trapped in disconnected systems actively degrades your ability to act. This isn't an IT problem to be solved with another dashboard. It's an operational crisis where the cost is measured not in software licenses, but in the thousands of dollars lost per minute of hesitation, in the rework from preventable errors, and in the collective burnout of your best people playing "data detective" instead of doing their jobs.

The Four Silent Killers in Your Data Pipeline

Every operation has a data pipeline, the flow from raw machine signals and field reports to the insights that should drive action. In manufacturing and construction, this pipeline is hemorrhaging value through four specific, concrete leaks. Plugging them is the difference between intelligence and noise.

1. Dark Data: The Ignored Warning Siren

- What It Means for Your Operation: You are collecting vast amounts of diagnostic data from sensors and machines but not analyzing it. This "dark data" contains the early-warning signals of impending failures.

- Your Concrete Pain Point: You miss these signals entirely. The result is not a gradual issue but a sudden, catastrophic breakdown. For instance, a $250,000 CNC mill fails without warning, causing 48 hours of unplanned downtime. The infuriating truth? The vibration data that clearly predicted the bearing failure was being stored but never monitored, turning a preventable maintenance task into a six-figure disaster.

2. Siloed Data: The Disconnected Reality

- What It Means for Your Operation: Critical information is trapped in separate, disconnected systems. Your MES doesn't talk to your ERP, and field reports never reach the project management software. Teams are literally working from different playbooks.

- Your Concrete Pain Point: This fragmentation causes catastrophic errors in execution. A common scenario: Sales accepts a rush order with custom specifications, but Production never sees the notes. The shop builds the standard product, leading to $15,000 in scrap, a missed critical deadline, and an irate key customer. The cost isn't just financial; it's a blow to your team's morale and your company's reputation.

3. Bad Data: The "Garbage In" Cascade

- What It Means for Your Operation: Inaccurate, inconsistent, or manually mislogged information enters your system. One small error corrupts every downstream decision that relies on that data point.

- Your Concrete Pain Point: A single keystroke error creates a domino effect. An operator manually logs a batch count incorrectly. Your planning team, trusting the system, bases a week's production schedule on this bad data. This causes a cascading parts shortage that idles an entire production line for a shift. You're now paying labor for zero output while scrambling with expedited shipping fees to recover.

4. Slow Processing: The Crippling Decision Lag

- What It Means for Your Operation: There is a massive, unacceptable delay between an event occurring and that information becoming an actionable insight for decision-makers. Data is stuck in transit or in a queue.

- Your Concrete Pain Point: You cannot act on what you don't know in time. A safety incident or near-miss is logged in a field app but doesn't sync to the central dashboard for hours. Because of this lag, you cannot issue an immediate fleet-wide safety alert. Consequently, a similar, preventable incident occurs at another site that same afternoon. The human and regulatory costs are immense, and the delay in data processing is directly to blame.

Each of these leaks transforms data from an asset into a liability. They create a "Latency Tax" that you pay daily through lost money, time, and control. The modern operational leader's mandate is to plug these leaks not with more dashboards, but with a connected, intelligent system that turns raw data into immediate, contextual understanding.

From Siloed Systems to Tribal Knowledge Drain

The problem extends beyond software. The most critical data in your operation - the tribal knowledge of your veteran workforce - resides in the most fragile silo of all: human memory. When your lead electrician, who can diagnose a motor fault by its sound, retires, that "data" is permanently deleted. The 25-year superintendent who intuitively knows which soil conditions will delay excavation by two days doesn't have a "system" to log that wisdom. You're not just losing people; you're losing the institutional memory that keeps your operation running. Replacing this with generic AI is impossible; the AI has no data to learn from.

Why Your Current "Solutions" Are Making It Worse

Operations Managers are natural problem-solvers, so the response to these leaks is often to add more tools: a better dashboard here, a new project management app there. This is the point solution trap, and it's a form of operational debt.

- The Integration Illusion: You're told the new tool has an "API." What you're not told is that building a stable, real-time integration is a multi-month, high-risk engineering project. In fact, research indicates that 84% of data integration projects fail or partially fail. The result is a "middleware graveyard" and more orphaned data.

- Dashboard Fatigue: A dashboard is a passive report. It shows you a problem (e.g., "pressure dropping") but provides zero context (e.g., "This machine is running the high-margin Job #4472; stopping it now costs $2,800/min, but the replacement part is in stock and a certified tech is 10 minutes away"). You still have to bridge that gap yourself, under pressure.

- The AI Pilot Purgatory: You pilot a predictive maintenance AI. It works in the controlled environment of Plant A but fails utterly in Plant B. Why? Because Plant B's historical data is in a different format, stored in a different legacy system. The AI isn't dumb; it's starved of a consistent intelligence layer.

The Intelligence-First Architecture: A Practical Blueprint

The alternative isn't a bigger dashboard or a more expensive AI model. It's a fundamental shift from a "tools-first" to an "intelligence-first" architecture. This is what we at Salfati Group term Organizational Intelligence (OI) - a cognitive layer that sits above your existing systems, not to replace them, but to make them collectively smarter.

For the Operations Manager, this translates from abstract pain to concrete relief. Here’s how OI plugs the leaks in your pipeline:

- For the Siloed & Dark Data Leak: Instead of a risky, all-or-nothing integration project, we deploy a Universal Data Fabric. Think of it as a translator that connects to your ERP, MES, field apps, and even spreadsheets in real-time. It doesn't move all the data to one place; it creates a live, unified view without the migration nightmare. Suddenly, the project manager in the trailer sees the same real-time inventory count as the procurement specialist at HQ, sourced from the same system.

- For the Tribal Knowledge Leak: We systematically help you capture and encode expertise. Using structured workflows within the tools your teams already use (like Microsoft Teams or Slack), we prompt your retiring machinist to document "that Tuesday adjustment" for Machine 7. This isn't stored in a static manual; it's encoded as a living rule: "If Machine 7 is running alloy X on a Tuesday, suggest calibration check Y." The expert's wisdom becomes an asset that outlives their tenure.

- For the Slow Processing & Bad Data Leak: This is where Sentient Workflows activate. When a sensor detects an anomaly, the system doesn't just flash red. It instantly queries the data fabric: What job is this machine running? What's the margin? Is the part in stock? Who is the nearest qualified technician? In seconds, it surfaces not just an alert, but a decision-ready prescription with full context, eliminating hours of investigative latency.

Your 90-Day Intelligence Audit: From Paralysis to Action

You don't need to boil the ocean. Transformation starts by proving value in one critical flow. Use this audit to identify your highest-cost latency point:

- Map Your Most Painful Decision: Identify the recurring decision that causes the most stress and delay. Is it responding to equipment faults? Approving change orders? Allocating crews to unexpected site issues?

- Trace the Data Journey: Follow the information needed for that decision. How many systems does a person have to log into? How many spreadsheets are manually cross-referenced? Where do they have to call or walk to someone to get a missing piece?

- Quantify the Latency Tax: Put a dollar figure on the delay. If it takes 45 minutes to dispatch the right crew to a breakdown, what is the cost of that downtime in lost production? If a change order approval takes 5 days, what is the cost of the work stoppage?

- Pilot an Intelligence Layer: Pick that one decision flow as a pilot. Implement a focused data fabric connection for the relevant systems. Encode the decision logic of your best performer. Measure the reduction in time-to-action and the dollars saved.

A Final, Provocative Truth

The future of operational leadership is not about managing more widgets or schedules. It's about managing intelligence velocity. The companies that will dominate the next decade aren't the ones with the most AI pilots; they are the ones that have built a sentient nervous system for their operations, where data flows freely, expert wisdom is cumulative, and the system empowers people to act with precision and speed.

Your competitive edge is no longer locked in a machine or a software license. It's trapped in the gaps between them. The question for 2026 is not what new tool to buy, but what kind of intelligence you will architect to set your team and your operations free.

Salfati Group partners with operations leaders in construction and manufacturing to build Organizational Intelligence. We don't sell point solutions; we co-create the cognitive layer that turns fragmented data and tribal knowledge into your most durable competitive advantage.